Vibration analysis program and oil analysis using Spartakus

Our client, a major mining company, had just put one of its factories back into operation. From the start, managers wanted to instill a culture of reliability and proactive management of assets and equipment.

Vibration analysis and oil analysis were implemented systematically and the results were deployed in the Spartakus platform.

Spartacus is a reliability management software that enables maintenance personnel to define maintenance strategies, create inspection routes, perform preventive inspections on desktop, mobile or tablet, compile equipment status and prioritize corrective actions according to their priority status, in addition to monitoring KPIs.

Preventing Unplanned Shutdowns

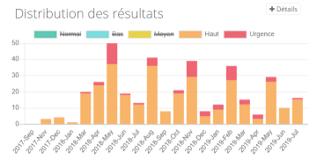

During the first six months, many high priority issues were identified that were on the verge of shutting down the plant. After resolving these problems, subsequent alerts turned out to be of lower priority and made it possible to see potential failures coming much earlier.

The Impact

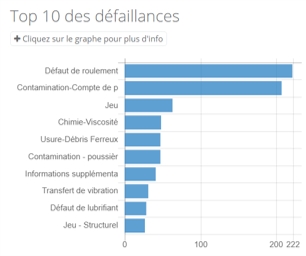

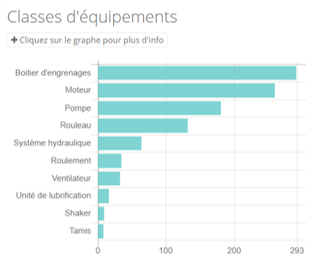

In just a few months, the implementation through Spartakus of the vibration programs, then the oil analysis, and the continued presence of one of our technicians on site have resulted in a 50% reduction in high priority alerts. In addition, Spartakus has enabled analytical KPIs such as Pareto of fail codes and problematic equipment and establishing problematic equipment classes geared towards the continuous improvement of the plant's reliability.