Planning and preparation of work

Prepare the shutdown schedule of your equipment for calibration, inspection, modification and repair. Furthermore, all tasks are conducted in accordance with occupational health and safety standards.

Multidisciplinary team

We put together teams based on your needs, among our specialists in the following areas:

- Engineering

- Automation

- Instrumentation

- Control and safety valves

- Electrical

- Mechanical

- Reliability

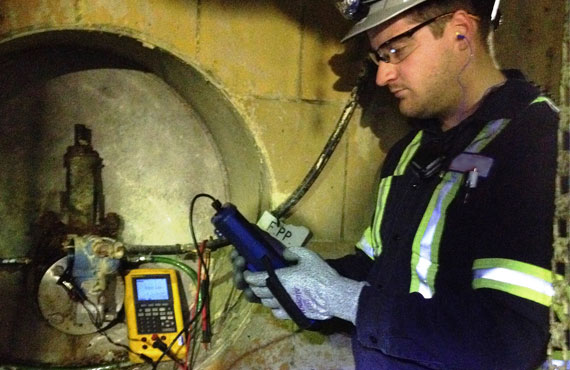

Calibration, optimization and repair of instruments

Execute the shutdown schedule of your equipment for calibration or verification purposes to ensure achievement of objectives and avoid surprises upon restarting.

Respect of timelines and budget

Our shutdown managers ensure effective communication of the work progress and a tight control of the established timelines and budget.

Health and Safety

- Our on-site staff members all follow the course on health and safety on construction sites given by ASP.

- We apply the occupational health and safety rules of our customers as well as those of Laurentide Controls.