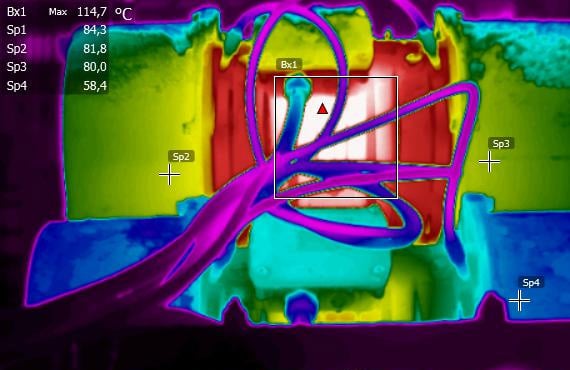

When a piece of equipment or a component malfunctions, a change in temperature usually occurs.

When it comes to mechanical equipment, the nature of a defect will generate a change in temperature either through friction (lubrication), misalignment (of pulleys and/or belts), impact, or mechanical wear.

It is difficult to observe and identify these changes with the naked eye.