Before fixing a problem, it must first be correctly identified.

Our client, a large-scale mining company facing fierce competition, needed to reduce losses related to mechanical breakdowns in order to remain financially competitive. Sustainably achieving this aim meant establishing a culture of reliability with a vision of daily proactive asset health management.

Laurentide Controls technicians and engineers, who were called to work on this project, used the Spartakus platform to review preventive maintenance tasks associated with 16 at-risk assets.

Exploring a solution

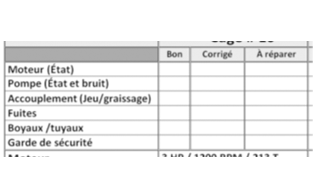

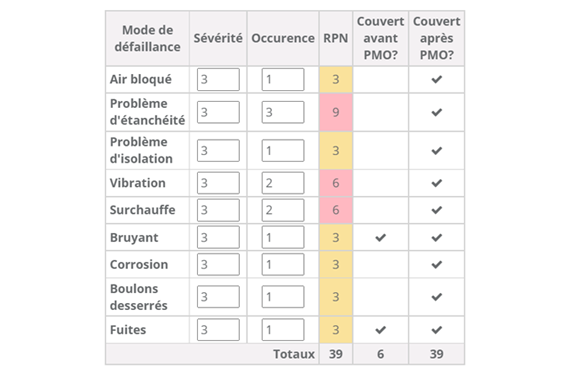

The first step was to analyse the machinery, which is large and complex, to identify their inherent failure modes. It became rapidly apparent that there were significant time lapses in weekly and monthly inspections.

Our impact

In a single month, the new PM implementation in Spartakus allowed our client to discover 8 major problems ahead of time: pumps on the verge of breaking, clogged lubrication nozzles and insidious oil leaks.

With a systematic analysis of failure modes, as well as a rigorous PM/PDM routes management process as set in Spartakus, it is possible to rapidly and efficiently compensate for gaps and pitfalls within the current maintenance strategy.