Pumps are often used for critical functions in various industries, such as water treatment and distribution, oil and gas extraction, power generation and chemical processing. It is therefore crucial to ensure that pumps are operating at optimal levels to avoid costly downtime and potential safety hazards. Vibration monitoring is therefore crucial to the proper operation of any industrial facility. However, while many companies are aware of the benefits of a vibration analysis program, they do not always have the resources or expertise to implement an effective in-house program.

Our website uses cookies. By continuing to browse our site you are agreeing to our Cookie Policy.

Vibration Monitoring

Get real-time information on vibration levels

Advanced detection and analysis capabilities for early problem identification

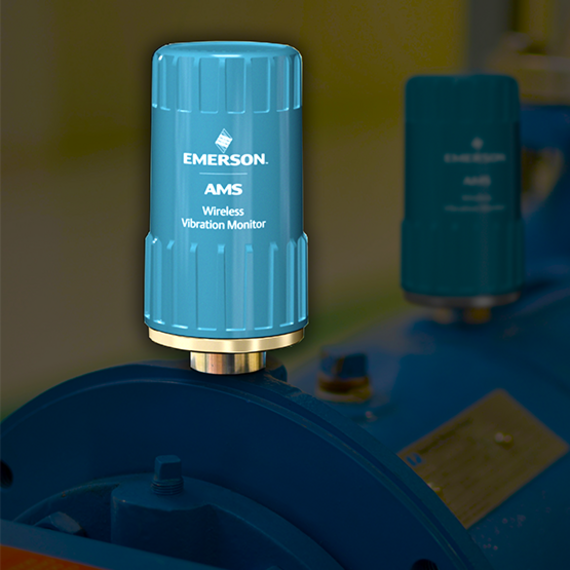

As the leader in vibration analysis technology, Emerson's AMS line offers unparalleled detection and analysis capabilities for machine health monitoring. The AMS 2140 Machinery Health Analyzer provides periodic data collection, the AMS Wireless Vibration Monitor provides monitoring capabilities, and the AMS 6500 Machinery Health Monitor and AMS Asset Monitor provide constant data collection. These technologies help identify potential anomalies before they become problems, resulting in improved uptime and overall efficiency.

Our solutions provide accurate and timely equipment vibration data, enabling maintenance and operations personnel to make informed decisions. Our solutions are customizable and flexible, allowing easy integration into existing systems and processes. Don't wait for potential problems - take proactive action with our vibration monitoring solutions.

Benefits:

- Keep your equipment running smoothly and prevent downtime.

- Get alerted of any potential problems before they become serious.

- Ensure the safety of your employees and avoid costly repairs.

Our solutions provide accurate and timely equipment vibration data, enabling maintenance and operations personnel to make informed decisions. Our solutions are customizable and flexible, allowing easy integration into existing systems and processes. Don't wait for potential problems - take proactive action with our vibration monitoring solutions.

Benefits:

- Keep your equipment running smoothly and prevent downtime.

- Get alerted of any potential problems before they become serious.

- Ensure the safety of your employees and avoid costly repairs.

To achieve the operational excellence worthy of your investments, contact us today.

CONNECT WITH OUR DIGITAL TRANSFORMATION TEAM

CONNECT WITH OUR DIGITAL TRANSFORMATION TEAM